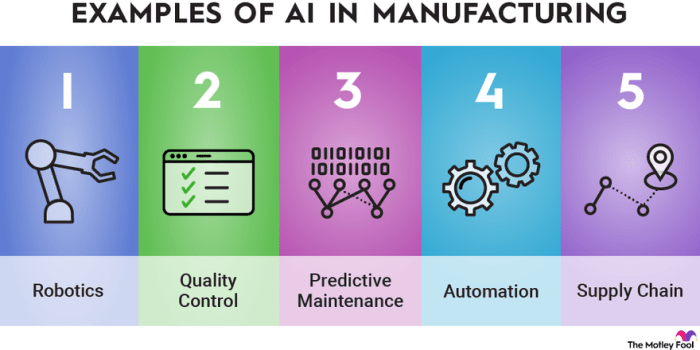

AI applications in manufacturing are reshaping the industry with cutting-edge technology and innovation. From predictive maintenance to quality control, AI is paving the way for smarter and more efficient manufacturing processes.

Overview of AI Applications in Manufacturing

AI applications in the manufacturing industry involve the use of artificial intelligence technologies to enhance and optimize various processes involved in production. AI plays a crucial role in revolutionizing traditional manufacturing methods by enabling automation, predictive maintenance, quality control, and resource optimization.

Automation in Manufacturing

AI-driven automation in manufacturing involves the use of robotics and smart machines to perform repetitive tasks with precision and efficiency. These systems can work around the clock without fatigue, leading to increased production output and reduced operational costs.

Predictive Maintenance

AI algorithms can analyze data from sensors and equipment to predict potential issues before they occur. This proactive approach to maintenance helps prevent costly downtime and ensures that machinery operates at optimal levels.

Quality Control

AI-powered systems can inspect products in real-time to identify defects or deviations from quality standards. This ensures that only products meeting the required specifications are passed along the production line, reducing waste and improving overall product quality.

Resource Optimization

AI can optimize resource utilization by analyzing data on production processes, energy consumption, and supply chain logistics. By identifying inefficiencies and areas for improvement, manufacturers can enhance operational efficiency and reduce environmental impact.

Predictive Maintenance with AI

Predictive maintenance is a key application of AI in the manufacturing industry. By using advanced algorithms and machine learning, AI can predict when equipment is likely to fail, allowing manufacturers to schedule maintenance proactively and avoid costly downtime.

Benefits of Implementing AI for Predictive Maintenance

- Reduced downtime: AI can predict equipment failures before they happen, allowing for timely maintenance and minimizing unplanned downtime.

- Cost savings: By preventing breakdowns and extending the lifespan of machinery, manufacturers can save on repair costs and maximize the efficiency of their operations.

- Improved safety: Predictive maintenance ensures that equipment is in optimal condition, reducing the risk of accidents and ensuring a safe working environment for employees.

Real-World Examples of Companies Using AI for Predictive Maintenance

- General Motors: GM utilizes AI to monitor the performance of its manufacturing equipment and predict potential failures. This proactive approach has helped GM reduce maintenance costs and increase overall equipment efficiency.

- Siemens: Siemens uses AI-powered predictive maintenance to optimize the performance of its industrial machinery. By detecting issues early on, Siemens can prevent breakdowns and maintain a smooth production process.

- Schneider Electric: Schneider Electric leverages AI algorithms to analyze data from sensors installed on its equipment, enabling the company to anticipate maintenance needs and ensure the reliability of its manufacturing processes.

Quality Control and Inspection Using AI: AI Applications In Manufacturing

AI technologies play a crucial role in improving quality control and inspection processes in manufacturing. By harnessing the power of artificial intelligence, manufacturers can enhance their ability to detect defects, ensure product consistency, and ultimately deliver high-quality products to consumers.

AI-Powered Tools and Techniques for Quality Control

- Computer Vision: AI algorithms analyze images and videos to identify defects or anomalies in products during the manufacturing process.

- Machine Learning: By training algorithms on historical data, machine learning models can predict potential defects and recommend corrective actions.

- Robotic Inspection: AI-powered robots equipped with sensors can conduct detailed inspections on products with high precision and accuracy.

- Natural Language Processing: AI can analyze text data from customer feedback or quality reports to identify patterns and trends that may indicate quality issues.

Impact of AI on Reducing Defects

AI has a profound impact on reducing defects and improving product quality in manufacturing by:

- Enhancing Accuracy: AI technologies can detect defects with higher accuracy than human inspectors, leading to fewer errors in the production process.

- Real-Time Monitoring: AI enables real-time monitoring of production lines, allowing manufacturers to address quality issues as soon as they arise.

- Predictive Maintenance: By predicting equipment failures before they occur, AI helps prevent defects caused by machinery malfunctions.

- Data Analysis: AI algorithms analyze large volumes of data to identify patterns that can help optimize production processes and minimize defects.

AI-Enabled Supply Chain Management

AI plays a crucial role in optimizing supply chain management in manufacturing by leveraging data analytics and machine learning algorithms to streamline various processes. Let’s dive into how AI is transforming supply chain management in the manufacturing sector.

Enhanced Inventory Management with AI, AI applications in manufacturing

AI enables manufacturers to achieve better inventory control by analyzing historical data, current trends, and demand forecasts. By utilizing AI-powered algorithms, companies can optimize inventory levels, reduce carrying costs, and prevent stockouts.

Demand Forecasting with AI

AI algorithms can analyze vast amounts of data to predict future demand accurately. By considering factors such as market trends, seasonality, and customer behavior, manufacturers can improve their forecasting accuracy, reduce excess inventory, and enhance customer satisfaction.

Logistics Optimization Using AI

AI in logistics helps manufacturers optimize transportation routes, reduce delivery times, and minimize costs. By leveraging AI-powered route optimization and real-time tracking systems, companies can enhance efficiency, improve delivery accuracy, and respond swiftly to changing market demands.

Advantages of AI for Supply Chain Optimization

Improved Efficiency

AI streamlines supply chain processes, reduces manual errors, and enhances overall operational efficiency.

Cost Savings

By optimizing inventory management and logistics, AI helps manufacturers minimize costs associated with excess inventory, transportation, and warehousing.

Enhanced Decision-Making

AI provides real-time insights and predictive analytics, enabling manufacturers to make informed decisions quickly and adapt to market changes effectively.